Heavy Vehicle Simulators (HVS)

The Heavy Vehicle Simulators (HVS) at the UCPRC provide California with unique, full-scale accelerated pavement testing capabilities. By applying years of traffic on instrumented test sections in a matter of months, the HVS allows researchers to evaluate new materials, designs, and construction methods under controlled conditions before they are widely implemented. This capability gives Caltrans rapid, field-validated data to reduce risk, improve durability, and advance innovations such as recycling, sustainable asphalt and concrete mixes, and long-life pavement strategies—making the UCPRC’s HVS program one of the most important pavement research assets in the United States.

The UCPRC has used HVS since the mid-1990s as the backbone of California’s accelerated pavement testing program. Launched in 1994 as a Caltrans–UC Berkeley partnership with collaborators from South Africa’s CSIR and Dynatest, the program deployed two South-African-developed HVS machines—one based at the Richmond Field Station for controlled testing of hot mix asphalt and a second for on-route testing of cement concrete on SR-14 near Palmdale. From 2000 to 2004, the Partnered Pavement Research Center expanded HVS use across asphalt, including fatigue and rutting performance, moisture sensitivity, and reflective cracking, as well as concrete studies, including dowel-bar retrofit and early-age concrete behavior. Laboratory and HVS test results were analyzed to guide Caltrans implementation. Later long-life pavement investigations integrated HVS findings to evaluate strategies for jointed plain concrete pavement and support practice updates.

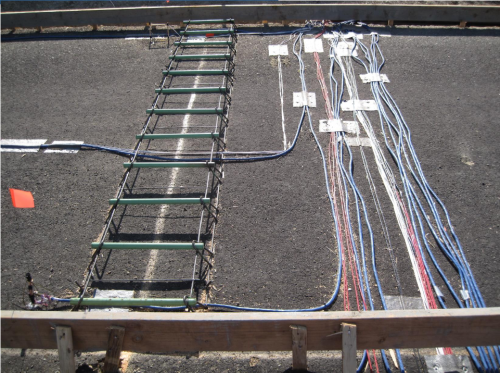

In subsequent years, UCPRC used HVS to evaluate new materials and systems: composite pavement (asphalt on concrete), two warm mix asphalt test tracks, three cold recycling test tracks, concrete overlay on asphalt, RHMA-G mixes with RAP, and balanced mix design assessments. HVS testing was also used to validate design approaches beyond conventional pavements, including permeable interlocking concrete pavement design tables developed through mechanistic-empirical methods. Structural applications included testing on the San Francisco–Oakland Bay Bridge East Span, where the HVS was used to assess seismic expansion joints under truck traffic, demonstrating the tool’s value for rapid, full-scale proof-of-performance testing. Collectively, these programs have provided Caltrans with validated designs, specification inputs, and implementation guidance across asphalt, concrete, recycled, and composite pavements.

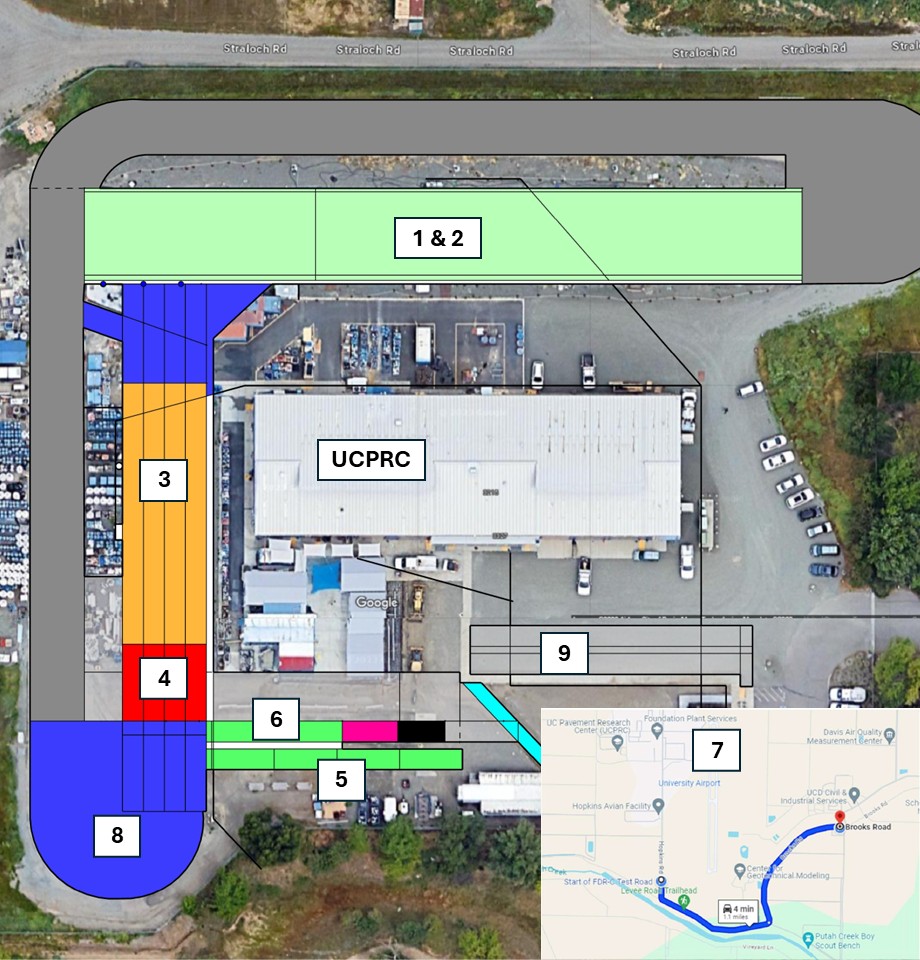

Test tracks

The UCPRC is host to 9 test tracks from 2023-2026.

LEGEND

1. FDR and CCPR North Track

Suppliers: Pavement Recycling Systems (Mix/Paving), Teichert (Millings), Graniterock (Equipment)

2. High RAP HMA on North Track

Suppliers: Granite Construction (Mix), Pavement Recycling Systems (Paving)

3. BMD Rutting West Track

Suppliers: Teichert (AB), UCPRC (Demo/Base), George Reed (Mix/Paving)

4. BMD Reflective Cracking

Suppliers: Teichert (AB), UCPRC (Demo/Base), Cemex/UCPRC (JPC), George Reed (Mix/Paving)

5. CCPR for Concrete Pavements (JPC

Suppliers: UCPRC (Demo/Base), Pavement Recycling Systems (Mix and Paving), Cemex (Mix), UCPRC (Paving)

6. Concrete Interlayers

Suppliers: Vanguard (LCB), Teichert Materials (RHMA-G), Cemex (PLC and OPC Mix), UCPRC (Paving)

7. RHMA-D on UC Davis Brooks-Levee FDR-C Test Road

Suppliers: Teichert Materials (Mix), Teichert Construction (Paving), Wright Asphalt, US Plyco, CRM, RARx (Binder/Rubber), UC Davis Campus (Site)

8. BMD Outer Track Overlay

Suppliers: George Reed (Mix/Paving)

9. Lab2Slab

Suppliers: A variety of suppliers provide innovative materials for testing.

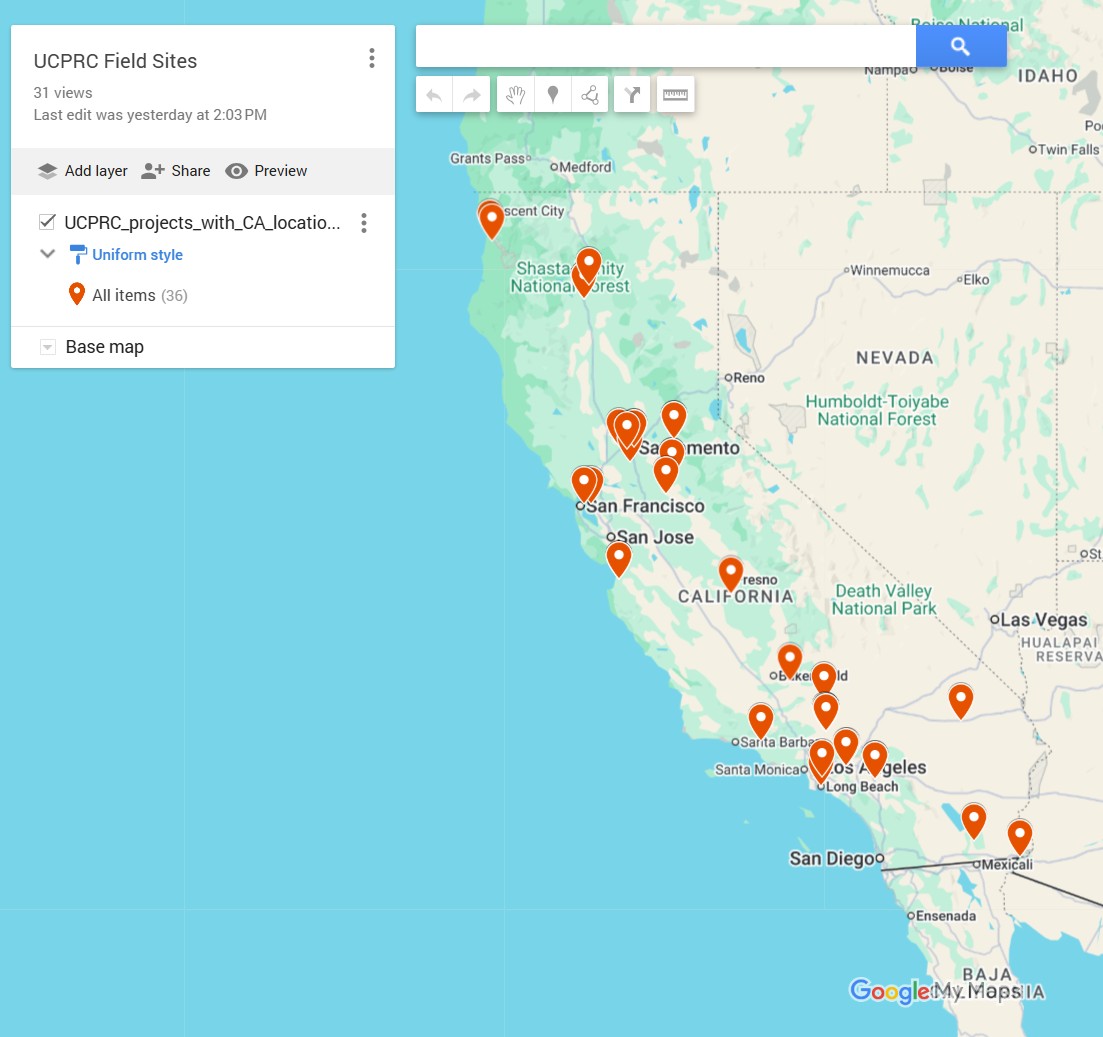

Field testing

The UCPRC has full capabilities for all types of materials sampling at the construction site and plant during field construction; non-destructive testing for deflection, roughness, macrotexture, and noise; and destructive testing, including coring and trenching. Our researchers instrument field test sections and perform follow-up condition surveys and other long-term monitoring of pavement performance. While our research includes international studies, our field test sites are primarily focused in the state of California. (This is a screenshot of a partial list of our field sites. A complete and interactive map is forthcoming.)

© Google